Πέμπτη 21 Φεβρουαρίου 2013

Embossing Hydraulic Press Model PRH 2200

Δευτέρα 18 Φεβρουαρίου 2013

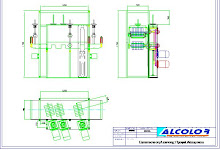

Hydraulic Press ALCOLOR PPH 1500

Τετάρτη 29 Δεκεμβρίου 2010

DIPDECOR Decorating by dipping

2. One water rinsing unit for the manual rinsing and rinsing water collection. Price 7.000 $

3. Collection of various design of DIPDECOR Films, totaling 300 sq meters. Price 2.200 $

Related Videos: http://www.youtube.com/watch?v=s294y_idvNA

http://www.youtube.com/watch?v=SxnzJIzjtfg&NR=1&feature=fvwp

http://www.youtube.com/watch?v=lm2Qb8S28cw

Τετάρτη 10 Μαρτίου 2010

Armoured Doors STEELCOLOR. Θωρακισμένη Πόρτα ασφαλείας Steelcolor

Ασφάλεια και στην πυλωτή με πόρτα και κάγκελα απομόνωσης του ακάλυπτου της οικοδομής. Απαγορεύομε έτσι την πρόσβαση των επίδοξων διαρρηκτών στον ακάλυπτο από τον δρόμο.

Τετάρτη 30 Σεπτεμβρίου 2009

DRYSPAL 2x3 Surface Cleaning Brush Machine

The aluminium profiles are fed several of the same height in parallel through polyurethane vulcanized and rectified driving rollers in a way that both upper and lower surface are in contact with the rotating brush discs as schematic figure below. The sanding discs are of 200 mm diameter and are at the following sequence:

1 couple upper and lower blocks of special sanding discs Original-KEMPER®-Sanding Star grit 80, 36 pieces each

1 couple upper and lower blocks of special sanding discs Original-KEMPER®-Sanding Star grit 180, 36 pieces each

1 couple upper and lower blocks of special sanding discs Original-KEMPER®-Sanding Star grit 200, 36 pieces each

This way we ensure the cleaning of the aluminium surface and elimination of the bonded chips remaining from the aluminium extrusions cut to length and consequent aging at the extrusion shop.

The quality Original-KEMPER®-Sanding Star is of recent German technology and ensures that no remaining from the sanding discs are left or bolted at the aluminium surface. So we avoid we often have with stainless steel or nylon brushes.

The sanding discs Original-KEMPER®-Sanding Star are so robust and strong that are also used for deburing the aluminium profiles edges. A very interesting feature for avoiding using paper adhesive tape for edge masking when profiles are wood imitation decorated.

In suitable points at the brush friction area there is suitable air injection for taking away the small quantity of brushed dust parts or chips or other impurities in the closed space around the brushes and profiles. A second air sucking circuit through cyclone and final filter is ensuring the maintenance of a negative pressure in the closed space of the machine so dust or impurities are not flying in the working space around the machine. This is an operation like with the powder coating Booths but much safer as the brushing machine booth has much smaller openings, so negative pressure is created easily and there is no risk of working environment contamination.

At the front of the Machine there is an upper opening plexiglass door, formatting one side of the brushing area booth as above described.

There is a free roller loading in feed table and a 7 meter free roller unloading table with the WAP put-at-side option for the automatic lateral movement and accumulation of the brushed aluminium profiles.

Weight: approx 1000 Kg

Motors 6 by 2 Kw each

Profile driving motors: 2 by 0,5 Kw each

Dust aspiration ventilator: 2 kw

Total motor power installed: 14 kw

Feed profiles velocity: 6 to 25 m/min

Total width of profiles’ feed: 300 mm

Production capacity of architectural profiles: up to 4 tons per hour

Depending on the profiles to be brushed and the required finish, other kind of brushes could be mounted too

Τρίτη 15 Σεπτεμβρίου 2009

SUBLIDECOR 700 Sublibag 1x10 in july 2005

Operation of the machine is shown at our manufacturing plant operated by ourselves, the machine manufacturers. We are experienced in manufacturing the machine but not in operating it. Actually our clients, after a few weeks experience, they operatre it much quicker and get much more decorated profiles per hour.

Τρίτη 16 Δεκεμβρίου 2008

Η φιλοσοφία ΑΛΚΟΛΟΡ

Η φιλοσοφία της Alcolor

Η συνεχής έρευνα για τις καλύτερες πρώτες ύλες.

Η διαρκής μελέτη των απαιτήσεων του κλάδου σε κάθε στάδιο.

Η αναζήτηση και συνεργασία με τους μεγαλύτερους οίκους του εξωτερικού.

Η υποστήριξη και εφαρμογή της τελευταίας τεχνολογίας στα μηχανήματα μας.

Η άμεση επαφή με τον πελάτη, η παροχή τεχνογνωσίας και υποστήριξης, το εξειδικευμένο service, οι υψηλές προδιαγραφές και τα πιστοποιητικά, είναι η εγγύηση μας για το καλύτερο τελικό προϊόν.

Αυτά είναι τα πλαίσια και η δομή πάνω στην οποία είναι χτισμένη όλη η φιλοσοφία της ΑΛΚΟΛΟΡ.

Στα πλαίσια αυτά προμηθεύουμε τις βιομηχανίες παραγωγής, εμπορίας και βαφής προφίλ αλουμινίου με σειρά μηχανημάτων βαφής και διακόσμησης ξύλου με την μέθοδο της σουμπλιχρωμίας SUBLIDECOR, μηχανήματα που κατασκευάζομε στην Ελλάδα και στην Μέση Ανατολή.

Παράλληλα υποστηρίζουμε τους χρήστες της σουμπλιχρωμίας με τις κορυφαίας ποιότητας πρώτες ύλες για την λειτουργία των μηχανών απομίμησης ξύλου, τα χρώματα-βάσεις του οίκου BECKER polveri και τα φιλμ σχεδίων ξύλου του οίκου ΜIROGLIO SUBLITEX.

Επίσης κατασκευάζουμε πλήρη σειρά μηχανημάτων προστασίας και συσκευασίας βαμμένων προφίλ αλουμινίου PTA εφαρμογής αυτοκόλλητης ταινίας προστασίας και WAP συσκευασίας και περιτύλιξης με χαρτί. Υπάρχουν διάφορα μοντέλα αναλόγως την παραγωγικότητα και τις ιδιαιτερότητες κάθε πελάτη.

Διαθέτουμε μία πλήρη σειρά εργαστηριακών οργάνων για τον έλεγχο αντοχής της βαφής των πιστοποιητικών QUALICOAT και ένα εξειδικευμένο ηλεκτρονικό καταγραφικό όργανο μέτρησης θερμοκρασίας φούρνου για τα προφίλ αλουμινίου του οίκου TQC.

Επίσης διαθέτουμε μία γκάμα των κορυφαίων ηλεκτρονικών οργάνων μέτρησης του πάχους βαφής (παχύμετρα) για σιδηρούχο η μη σιδηρούχο υπόστρωμα του οίκου DEFELSKO.

Τέλος διαθέτουμε μία ολοκληρωμένη σειρά αυτόματων η χειροκίνητων συστημάτων ηλεκτροστατικής βαφής πούδρας, τεχνολογίας παλμικής φόρτισης Pulse Power, παγκόσμια πατέντα του Ιαπωνικού οίκου PARKER IONICS.