Oil

Hydraulic Press specially designed for embossing aluminium sheets for

door Panel production

Embossing

Press

Model

PRH

2200

Pressing

Force 2200 ton

With

the ‘’balloon’’ type pressing principle

We provide the engineering

of the dies too with all the service involved: Definition of the

embossing profile according client’s preferences, embossing trials

for sampling the profile, designing of the panels’ embossed forms

and manufacturing of the dies themselves.

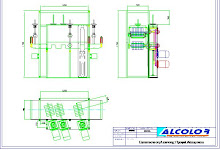

Special Oil Hydraulic Press 2200

M Ton for the embossing of the Aluminium Sheets destined to the Door

Panel fabrication.

The frame is of closed body and

incorporated type fabricated by tested quality steel profiles and

plates of

suitable thickness to withstand the

load and longer life . The frames are stress relieved.

The low noise hydraulic power pack unit

is designed as per international practices and assembled with

internationally reputed make

components.

Hydraulics and oil tank are mounted at

the side of the Press Body.

Precise machining of the structural

members is done after normalizing to get the required accuracies like

parallelism between platen and bed and

right angularity between bed and the pressing

platen.

A special high

endurance polyurethane rubber membrane of 7

mm thickness is installed on the

upper pressing bed for

providing the embossed form to the

Aluminium Sheet positioned on the special relief die below it.

The membrane touches the die after

the hydraulic oil is pressed in it conveniently to take the

form of the die.

The aluminium sheet of suitable

aluminium alloy in HO condition, which is placed in between, is

pushed against the die and takes its exact form.

The Pressing

capacity applied on the formation surface

is 2200 M Tons.

Hydraulic pump 10

HP

Maximum working pressure 125

bar

Electrics include PLC with operation

panel.

Simple operation of the Press with

securities for the operator.

Overall main body dimensions: 1760

x 2000 x 2000 mm, or 7500 x 2000 x 2000 mm including the

hydraulics unit, operation panel and the 2

sliding moving die support platforms.

Application of embossed sheets for Panel Doors manufacturing

An embossing die:

Embossing die and embosed sheet: