The machine is working dry without spending water and its inherent pollution problems. It is based on a new German technology sanding disc developed by Kemper GmbH, the discs model Original-KEMPER®-Sanding Star.

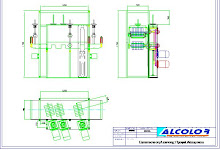

The aluminium profiles are fed several of the same height in parallel through polyurethane vulcanized and rectified driving rollers in a way that both upper and lower surface are in contact with the rotating brush discs as schematic figure below. The sanding discs are of 200 mm diameter and are at the following sequence:

1 couple upper and lower blocks of special sanding discs Original-KEMPER®-Sanding Star grit 80, 36 pieces each

1 couple upper and lower blocks of special sanding discs Original-KEMPER®-Sanding Star grit 180, 36 pieces each

1 couple upper and lower blocks of special sanding discs Original-KEMPER®-Sanding Star grit 200, 36 pieces each

This way we ensure the cleaning of the aluminium surface and elimination of the bonded chips remaining from the aluminium extrusions cut to length and consequent aging at the extrusion shop.

The quality Original-KEMPER®-Sanding Star is of recent German technology and ensures that no remaining from the sanding discs are left or bolted at the aluminium surface. So we avoid we often have with stainless steel or nylon brushes.

The sanding discs Original-KEMPER®-Sanding Star are so robust and strong that are also used for deburing the aluminium profiles edges. A very interesting feature for avoiding using paper adhesive tape for edge masking when profiles are wood imitation decorated.

In suitable points at the brush friction area there is suitable air injection for taking away the small quantity of brushed dust parts or chips or other impurities in the closed space around the brushes and profiles. A second air sucking circuit through cyclone and final filter is ensuring the maintenance of a negative pressure in the closed space of the machine so dust or impurities are not flying in the working space around the machine. This is an operation like with the powder coating Booths but much safer as the brushing machine booth has much smaller openings, so negative pressure is created easily and there is no risk of working environment contamination.

At the front of the Machine there is an upper opening plexiglass door, formatting one side of the brushing area booth as above described.

There is a free roller loading in feed table and a 7 meter free roller unloading table with the WAP put-at-side option for the automatic lateral movement and accumulation of the brushed aluminium profiles.

Weight: approx 1000 Kg

Motors 6 by 2 Kw each

Profile driving motors: 2 by 0,5 Kw each

Dust aspiration ventilator: 2 kw

Total motor power installed: 14 kw

Feed profiles velocity: 6 to 25 m/min

Total width of profiles’ feed: 300 mm

Production capacity of architectural profiles: up to 4 tons per hour

Depending on the profiles to be brushed and the required finish, other kind of brushes could be mounted too

Τετάρτη 30 Σεπτεμβρίου 2009

DRYSPAL 2x3 Surface Cleaning Brush Machine

Ετικέτες

aluminium profiles,

brush,

dryspal,

recoating,

surface cleaning

Εγγραφή σε:

Σχόλια ανάρτησης (Atom)

Have tried soft scotch-brite brushes for aluminium profiles mat finish and it worked nicely. Grit 400 at first stationand grit 800 for stations 2 and 3.

ΑπάντησηΔιαγραφή